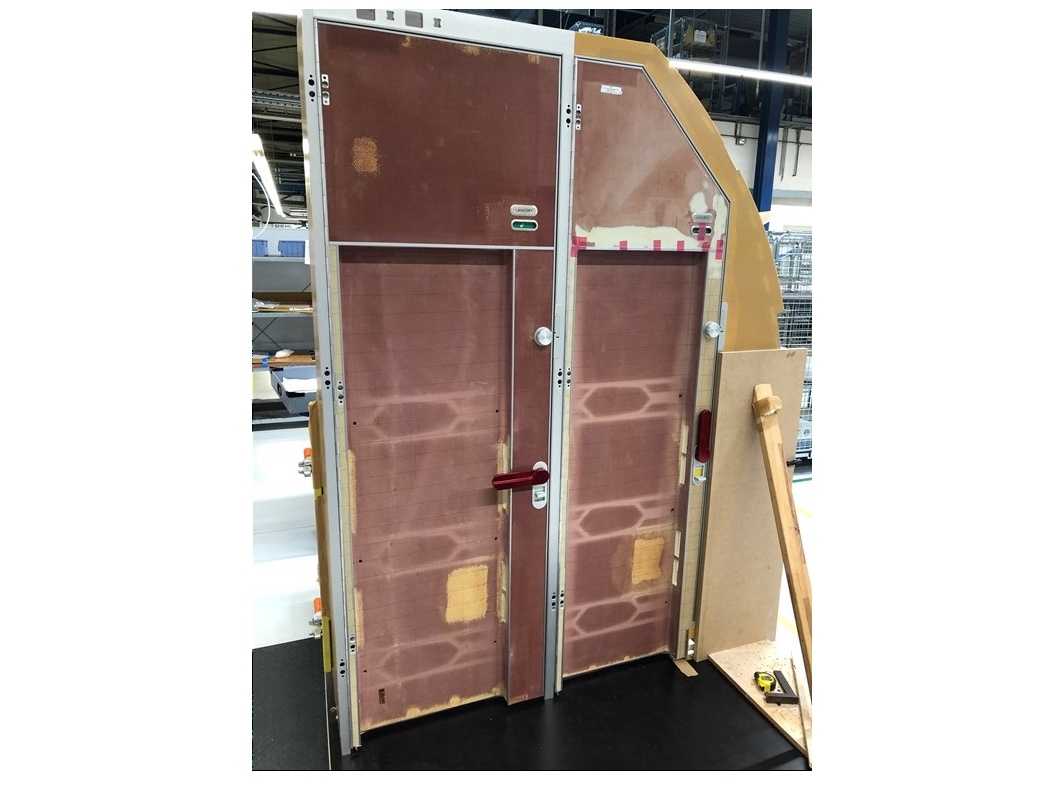

Aeroworks has extensive experience producing lavatory doors with stringent weight, flatness, and strength requirements.

These include both blade and bi-fold doors. Through tried and tested manufacturing processes, we are able to manufacture doors with very strict flatness and strength requirements.

We have the capability to test the doors for twist and bending and test that the doors retain their straightness after been put under load (twist and bending load).

These doors can be manufactured with imbedded metal brackets at the time of lamination or they can be secondarily bonded after curing and trimming depending on the type of insert.

Several different cores can be used to produce the lavatory doors and different cores can be used within a single door as well.

The different cores can be arranged in special patterns around the length of the door to maximize the strength whilst keeping the weight of the door as low as possible.

The use of the different cores can also help by reducing the amount of edge and core filler that needs to be used in order to achieve a good edge finish or bonding surface.

Depending on the specific customer requirements, the doors can be delivered bare, or with paint and/or décor material already applied to the surface.

Application of polyvinyl fluoride to flat doors is also an option if that is required.

The Aeroworks engineering team is always available to work with customers on the design of the doors that will meet their requirements whilst keeping the manufacturing costs as low as possible.