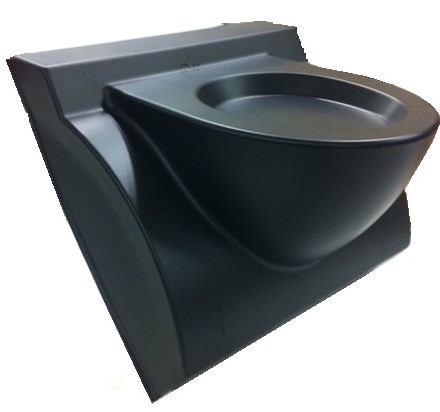

Aeroworks has many vacuum form experiences of large and complex shapes such as toilet shrouds and floor panels following the highest quality standards.

Our techniques allow us to provide very competitive pricing and quick prototyping.

Through a careful consideration of the thermoplastic materials by a tight collaboration with our suppliers, several production steps could be removed such as surfacing and painting.

These materials are high resistance against stains, chemicals, abrasion, and large impact.

They are easy to clean and therefore very suitable for use in applications such as toilet shrouds, floor panels and seat back shrouds which require constant cleaning.

This process also allows for a wide range of colors to be used and there is a wide option of FSTH compliant materials available should that be necessary.

These complex parts can also be assembled separately to achieve an even more complex construction whilst retaining the benefits of vacuum forming.

We have been able to achieve watertight constructions that retain their water tightness when pressurized.

Naturally, the combinations of vacuum formed, metal and composite parts are possible as well.

Please reach out to our experienced engineering team and they will be happy to help review the different options for your products and designs.