Testing is performed in accordance with the latest aerospace requirements and in addition, tests can be performed according to customer specific test procedures.

In 2016, our smoke and heat release chambers were modernized with the installation of state-of-the art equipment supplied by Marin Engineering, Dräger and Testo.

Our test bench (Testometric), flammability (Atlas) and conditioning chamber have been updated in previous years as well. With our modern test laboratory, we are ready to assist you with your testing needs.

See below the introduction video of our test laboratory:

Testing capabilities on our static test bench:

- Flatwise Tensile Strength ASTM C297/C297M

- Short Beam Flexure ASTM C393/C393M

- Peel or Stripping Strength of Adhesive Bonds ASTM D903

- Long Beam Flexure ASTM D7249 or D7249M

- Climbing Drum Peel ASTM D1781/DIN EN 2243-3

- Custom testing to customer specifications

Fire property testing capabilities

- Flammability per CS/FAR25.853, App. F, Part I (12 or 60 sec. vertical, horizontal, 60˚ or 45˚)

- Smoke Emission/Density per FAR/CS 25.853, App. F, Part V

- Toxicity per ABD 0031 (Airbus) or BSS 7239 (Boeing)

- Heat Release (OSU) per CS/FAR25.853, App. F, Part IV

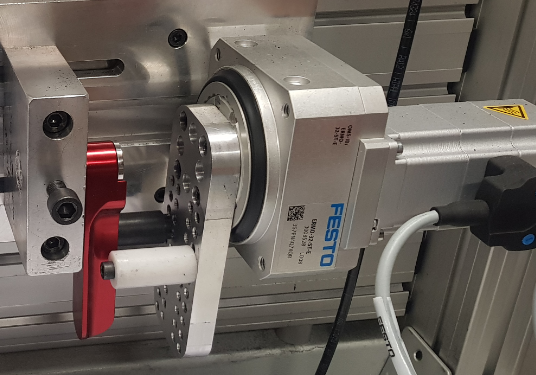

Endurance testing

Accelerated life cycle testing of interior hardware products like lavatory latches, which require a full operational cycle of in total 1.5 M cycles.

Retainer on cycle test bench

Overhead bin latch on cycle test bench

Test lab approval and accreditation

All testing is completed under our AS9100D certificate and the responsibility of EASA DOA organizations.

All test results are issued with a test certificate.