Aeroworks Eur, was founded in 2000. The company slowly expanded our customer base and Interior hardware product line and added Interior composite products to our list of capabilities around 2006.

Aeroworks is a healthy and thriving interior and composite production company now moving into our 20th year with high hopes for the future.

Aeroworks engineering designs, develops and qualifies all our products in house. Our hardware products consist of primarily machined aluminum parts, we then anodize finish and assemble all parts in house.

Aeroworks designs can also be modified to the customer specifications or wishes, and alternative finishes such as paint, powdercoat and special platings are within our capabilities.

Aeroworks strives to be as independent as possible. Our design and development center is in the Netherlands. We have 3D prototyping, manufacturing and qualification testing all carried out in house, in the Netherlands

All production engineering, serial manufacturing, finishing process, assembly and shipping are all carried out in our manufacturing facilities in Asia (Thailand and Laos).

Aeroworks is a company driven by customer support, flexibility, quality and a great turnaround time.

All our facilities are managed by European staff, to help serve our customers with engineering assistance, production support and keeping our quality at the highest level achievable.

Retainers and Intermediate Retainers

Aeroworks currently produces approximately 200,000 retainers per year. These are available in every shape, size and color.

These are used for trolleys, large and small, kickload retainers and compartment retainers and other usage.

Our intermediate retainers for trolley and standard container compartments, have the option for carbon shafts

Our carbon shafts (in place of stainless) have lowered the weight of such product by more than half and are 100% interchangeable with the current designs.

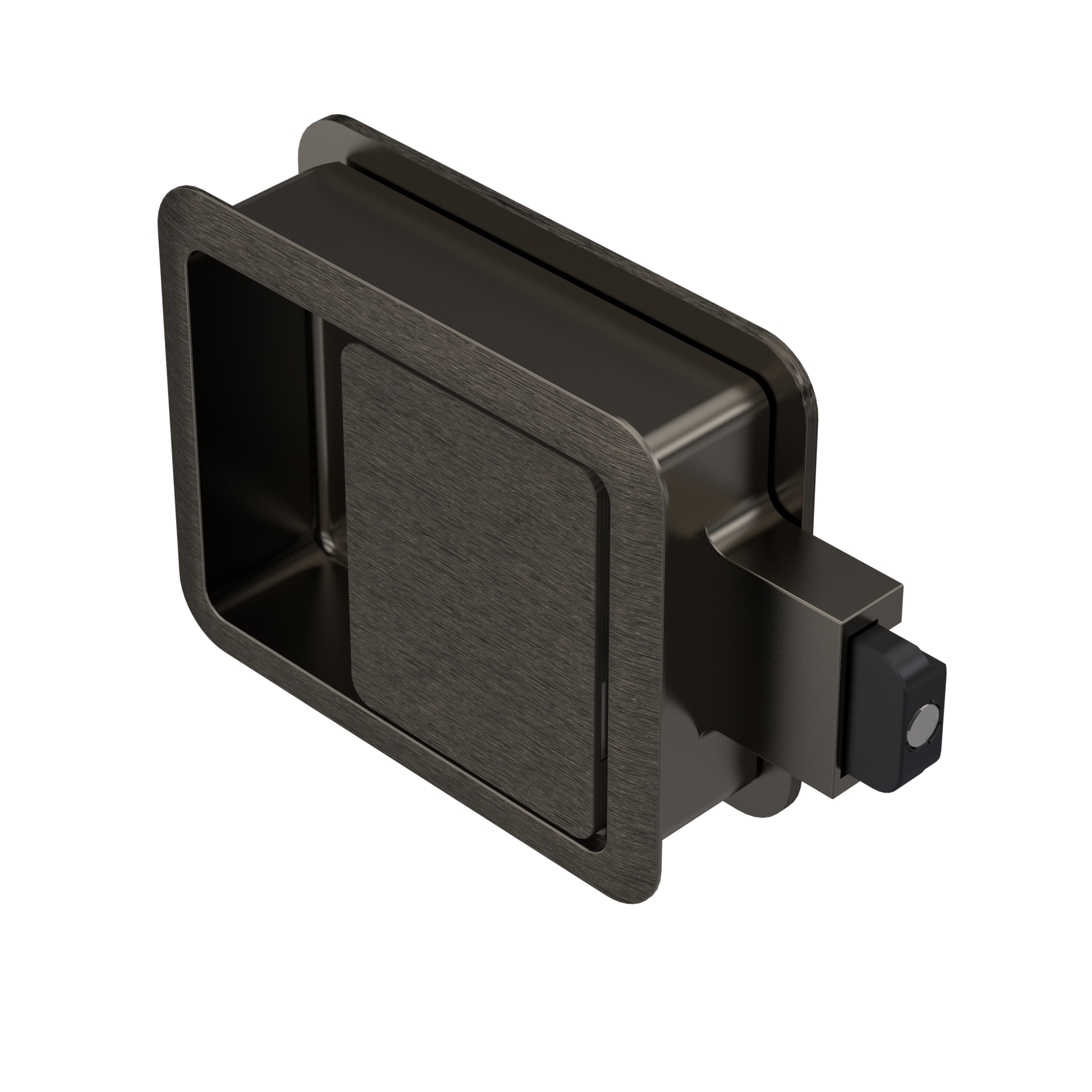

Latches, latches everywhere, galleys, stowage’s, closets, bar units, overhead bin and lavatories. Aeroworks has succeeded in designing and qualifying, latches for every need.

These are all tested to the most stringent specifications for every imaginable requirement. All cycle and load testing is carried out at our own development center in the Netherlands.

Magnet Latches and Magnet Strikers

Our magnet latch designs have been enthusiastically received by various customers and are being used on lavatory doors and internal compartments and baby change tables, galley compartments and drawers, stowage’s, bar units, and first class seating credenza programs.

These latches are quiet, and safe as the bolt remains retracted when disengaged. When closing the door, the latch engages automatically with the magnetic striker that accepts the latch bolt.

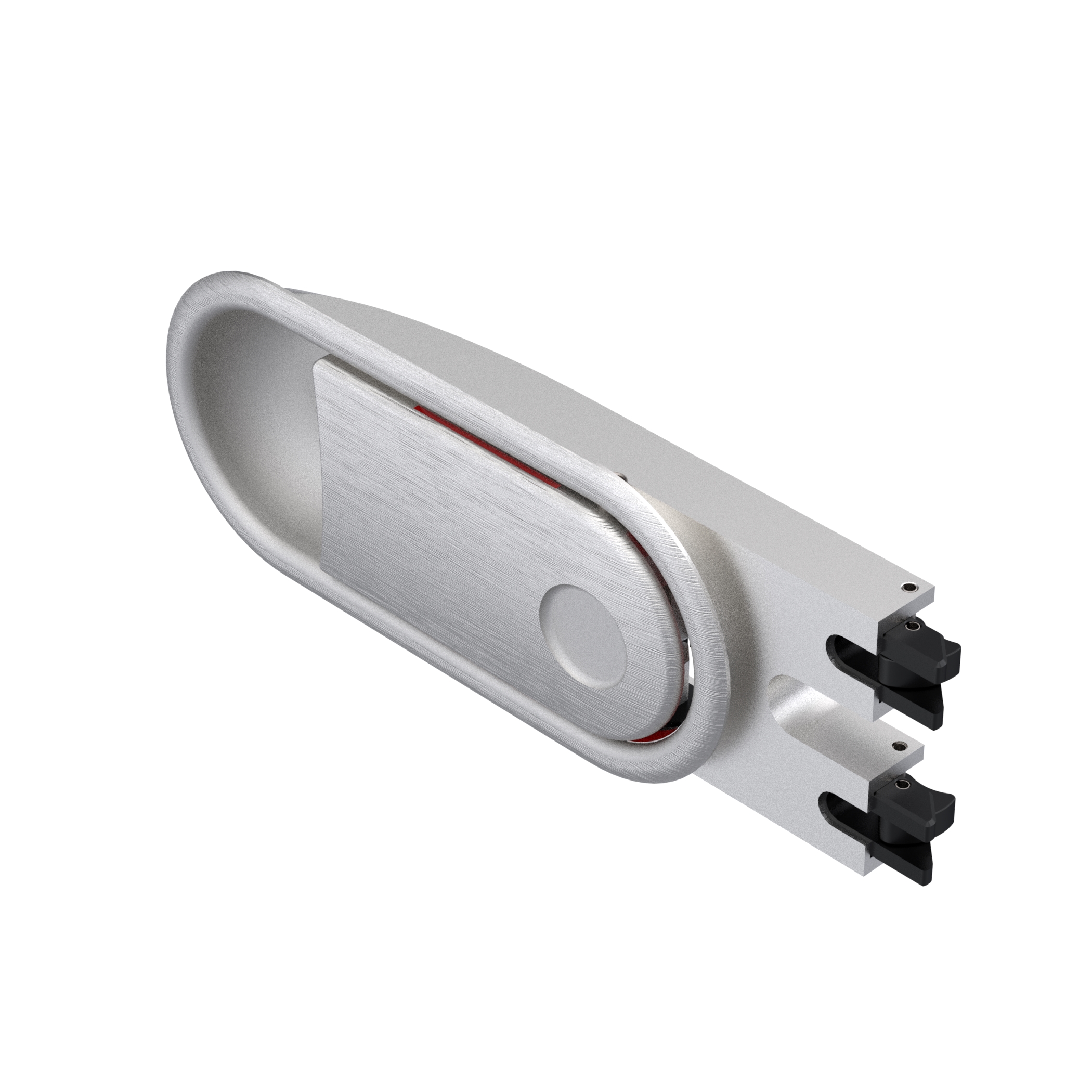

Lavatory Latches and Door Handles

The Lavatory latch and handle programs have been a success beyond our imagination.

Working closely with our OEM customers we have designed developed and qualified these blade, bi-fold latches and door handles for multiple programs.

We are currently manufacturing these on the A350, A330 Neo, A320 Airspace (with a magnet version), Space flex (aft galley / lav complex), 737 max and Pax plus and Embraer E2 lavatories.

Aeroworks new state of the art soft close extractor reduces the dreaded slam back, of the cable, which can causes some visual damage to a galley extrusions, but as good as cancels all the noise it produced when release and extracted back into position.

The new extractor is 100% interchangeable with the older model extractors so can be replaced very quickly in your galleys.

The extractor has been qualified to the most stringent requirements, which we have based on discussions with our OEM’s and the Aircraft OEM’s who have all dealt with this for years.

Slides in 3 sizes and lengths from 10 to 30+ inches, Coat hooks, ashtrays, paperclips, door hold open devices and cup holders are among other hardware that we have a wide variety of designs to fit you needs.